.

TITAN Z trailer system

TITAN Z trailer system

Technically perfect. Functional. User-friendly.

TITAN Z produces extremely cost-effective cement screed of the highest quality.

The three-axle semi-trailer is equipped with a compact machine unit modelled on the alpha CR series with a 55.4 kW DEUTZ diesel engine and a high-performance compressor.

The central component of the TITAN is the double-walled aluminium body including chassis.

The total capacity is 25 m³ of material (e.g. 19 m³ sand, 6 m³ binder).

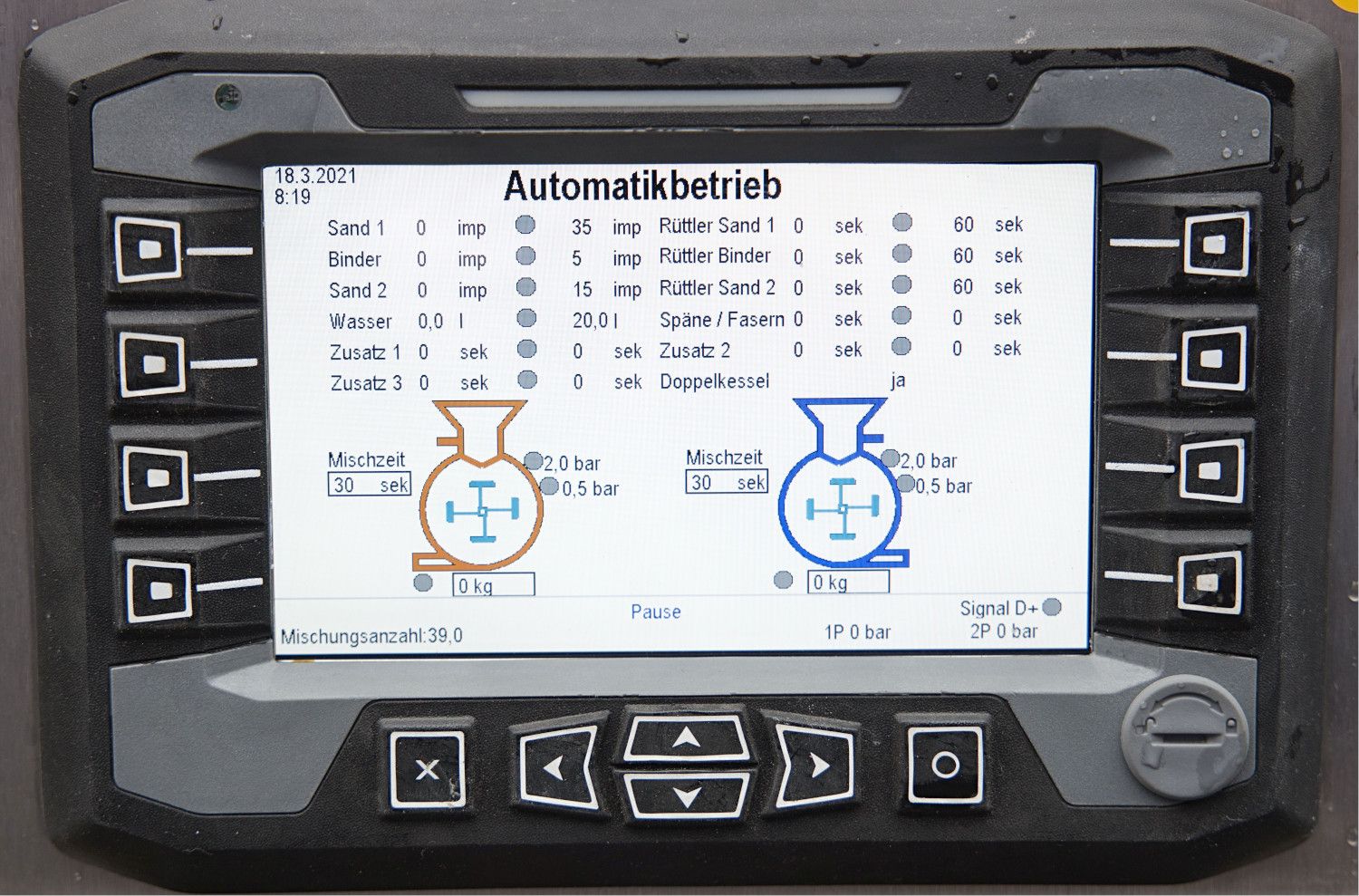

The previously entered mixture is started computerised with a button on the control cabinet with the “Danfoss” control panel at the rear. Also positioned in the rear is the high-quality stainless steel hose reel, which is height-adjustable and hydraulically driven. The reel can hold up to 120 m of feed hose.

There are many standard additional features, for instance high-pressure cleaner, scales, continuous storage compartment. Numerous technical configurations and customisations are possible, such as generator, pull-out large drawer as well as a fibre chopper.

Facts and figures

- Three-axle semi dump trailer

- 1. Axle as 2-side lift

- 3. Axle as self-steering axle – lockable from the cab and additionally by hand

- Body with double-walled aluminium design

- Standard size: 25 m³

- Body made to measure, chamber partitioning freely selectable

- Dimension in mm (LxWxH): 10700 x 2500 x 3250 (depending on the version)

- Empty weight approx. 10.5 t

- Equipped with extension hatch, injection device installed

.

- Water-cooled three-cylinder Deutz diesel engine with 55.4 kW (complies with valid Euro 5 exhaust emission standard)

- Innovative efficient cooling system with foldable fans

- Powerful BMS screw compressor with an air capacity of 6m³/min

- 260 litre mixer tank, hydraulically driven

- Hydraulic tank stainless steel 300 litres

- Fuel tank stainless steel 300 litres (with telescopic access ladder)

- Cover made of stainless steel

- Hose reel positioned in the rear, height adjustable, hydraulically driven

.

- Electric sliding roof with remote control

- Danfoss control with interchangeable modules – relay manually operable with fault indication

- Robust 6-channel Danfoss radio remote control

- Full-length storage compartment with roller shutters and load securing system

- Hydraulic high-pressure cleaner

- Large working light

- 2 vibrators for binder chamber

- 1 vibrator for sand chamber

- Weighing system via 3 load cells