.

BMS alpha E63

BMS alpha E63

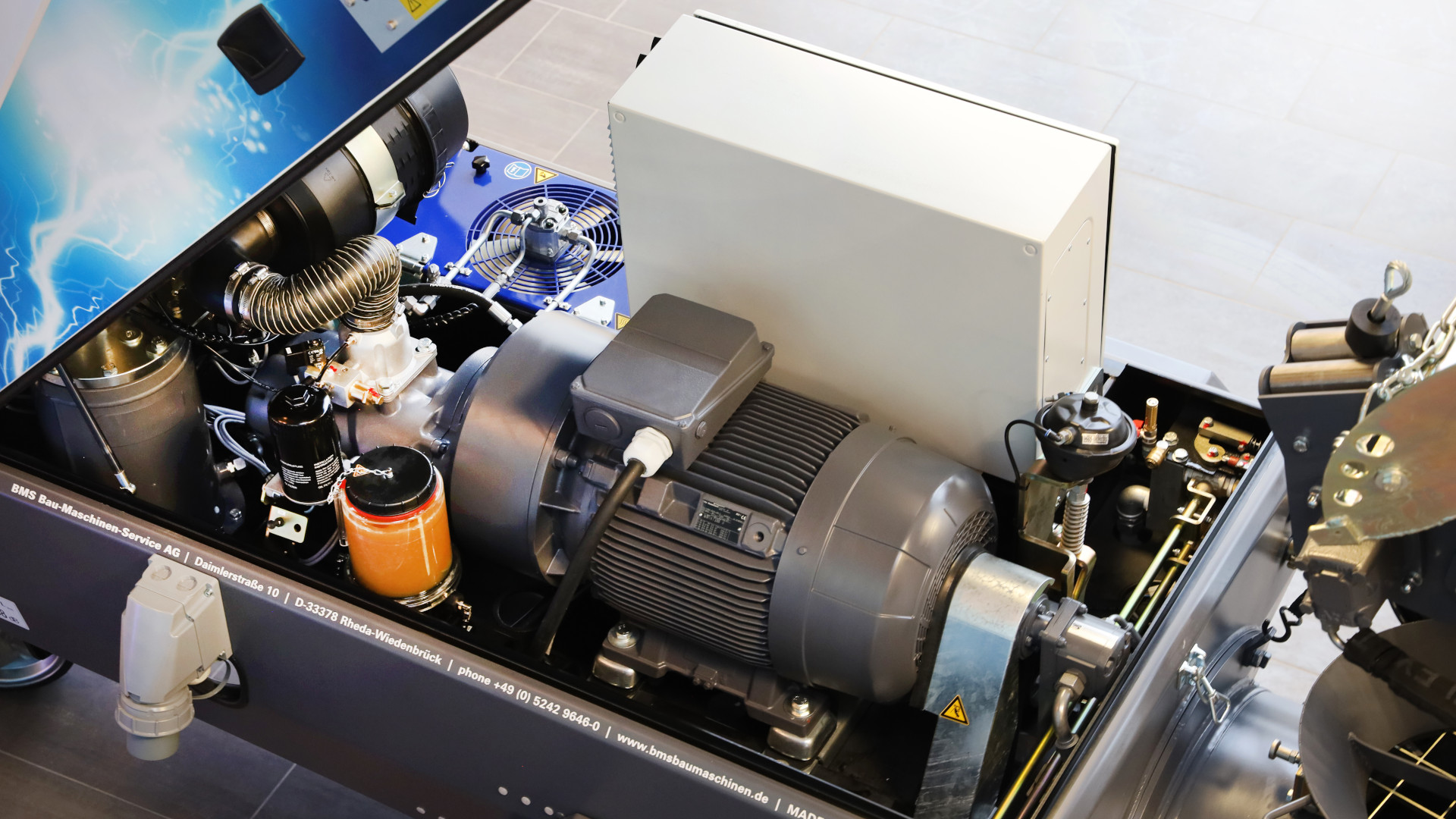

Alpha E63 has been developed particularly for the use on construction sites with conv entional electricity supply. With its frequency regulated three-phase current engine the alpha E63 can be connected to every power distribution provided on construction sites. Operational safety is guaranteed at all times. Performance may be adjusted from 50 to 63 Ampere on site. The 30 kW variable frequency engine lends alpha E63 all its power without producing exhaust pollution or CO2 emissions. Moreover, noise development is reduced significantly.

In countries with sufficient power supply on construction sites, such as Switzerland for example, the machine functions as well on 63 Ampere construction site power without frequency converter by only using a conventional star-delta switch.

In addition to the standard version, the machine is also available with feeder or feeder/scraper.

Technical facts:

- 30 kW electric engine – adjustable between 50 – 63 Ampere

- Oil-cooled BMS screw compressor; air power of over 4,5 m3/min.

- No CO2 emission, reduced noise development

- Conveying distance*: 180 m

.

- Safety shutdown at the dome sieve

- Automatic 2-bar shutdown

- Easy belt replacement at the mixer

- Mixing vessel from in-house manufacturing

- Stable and long-lasting stainless steel hood

- Highly rust resistant EPD-coated frame

- Stable fenders suited for deposal

- Lockable toolbox

.

- Integrated working light

- Height adjusting coupling device

- Sturdy chassis with mechanical overrun brakes and central height adjustment

- 1,9 t or 2,5 t axle as standard equipment

- High-strength wear plates